Example of order:

A high-low oil station its high pressure is 31.5MPa, output 2.5L/min ,and low pressure is 0.4MPa, output 25L/min

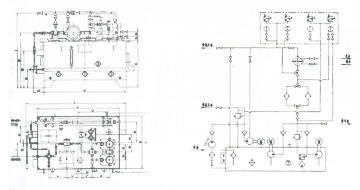

WGXYZ-25A high low oil station

Structure & Principle

This station is consisted mainly of oil tanker (magnetic core mesh filter inner),low pressure pump device ,high pressure pump device ,twin barrel magnetic core mesh filter , heater ,cooler ,manual high pump , pipeline ,valve ,instrument panel ,electric controller etc .

Before starting main machine ,starts the low pump ,when its low filling pressure reached normal ,stars the high pump which suction port is connected to the pipeline of low pump. The high oil through high check valve flows to the static pressure bearing .When the high pressure reached a curtain value ,starts the main machine ,slow runs or stops. After main machine running normally then stops the high pump (exception the low running ),but the low pump must operate ordinary . The low pump suction oil from tanker ,then sends it pass check valve ,twin barrel mesh filter , cooler to the static pressure bearing too ,to maintain the main machine running ordinary .After stopped main machine ,if want filling oil by high or low pump timely ,can control by time relay to lubricate the point interrupt.

The specific value of high or low pressure is controlled by high-low safety valve in the system.

In the ordinary running of main machine , one low pump is working ,and another one is standing by . As the system pressure down at a value wanted , starts the ready pump , and then stops it while normal . If the pressure downing on still ,must sent an alarm ,and consider stopping the main machine.

When the high plunger pump at fault , can fills oil by manual pump.

Set the filter before the cooler , make the low viscidity oil passes the filter earlier , one filter at working , and another one at standing by , controlled by handle switch valve.

Oil level higher or lower than a limit , are sent alarm by level signal , manual oil filling or stopping .

Back oil passes the magnet mesh filter prepared in the tanker ,and can absorb the iron particulate at same time.

Whole set of oil station is matched an instrument panel and an electric controller , to display operating data and to carry out at automatic , manual or alarm.

A bimetallic electric contact thermometer installed on the tanker , when oil temp is too low sends a signal ,to open the heater by handle ,and stops automatically when reached an appointed temperature.

A electric contact pressure type thermometer installed in the filling port , setting two limits of maximum and minimum temp needed ,to determine the cooler working or not.

Appearance and dimensions:

|

parameter/type |

WGXYZ | WGXYZ | WGXYZ | WGXYZ | WGXYZ | WGXYZ | ||

| 16A | 25A | 40A | 63A | 100A | 125A | |||

|

low system |

pump type | LBZ-16 | LBZ-25 | LBZ-40 | LBZ-63 | LBZ-100 | LBZ-125 | |

| output L/min | 16 | 25 | 40 | 63 | 100 | 125 | ||

| filling pressure MPa | 0.4 | |||||||

| filling ℃ | 40±3 | |||||||

| motor | type | Y90S-4,V1 | Y100L1-4,V1 | Y112M-4,V1 | ||||

| power | 1.1 | 2.2 | 4 | |||||

| velocity | 1400 | 1400 | 1440 | |||||

| tank m3 | 0.8 | 1.2 | 1.6 | |||||

|

high system |

pump type | 2.5MCY14-1B | ||||||

| output L/min | 2.5 | |||||||

| filling pressure MPa | 31.5 | |||||||

|

motor |

type | Y112M-6 B35 | ||||||

| power | 2.2 | |||||||

| velocity | 940 | |||||||

| filter precision mm | 0.08 | |||||||

| filter area m2 | 0.13 | 0.19 | 0.40 | |||||

| cooling area m2 | 3 | 5 | 7 | |||||

| consume of cooling water m3/h | 1 | 1.5 | 3.6 | 5.7 | 9 | 11.25 | ||

| power of heater kW | 3*4 | 3*4 | 6*4 | |||||

| demission mm | 1820*1130*1320 | 1880*1220*1650 | / | |||||

| note | the switch differential pressure of all fillter are 0.15MPa | |||||||

| type | DN1 | DN2 | DN3 | ND4 | L | B | H | L1 | B1 | H1 | L2 | L3 | L4 |

| WGXYZ-16,-25 | 10 | 25 | 50 | 25 | 1650 | 1230 | 1500 | 1330 | 1080 | 1000 | 1250 | 410 | 420 |

| WGXYZ-40,-63 | 25 | 32 | 65 | 32 | 1800 | 1430 | 1550 | 1480 | 1280 | 1050 | 1400 | 270 | 440 |

| L5 | L6 | L7 | L8 | B2 | B3 | B4 | B5 | B6 | B7 | H2 | H3 | H4 | H5 | H6 | H7 |

| 100 | 80 | 120 | 280 | 160 | 200 | 180 | 420 | 280 | 360 | 70 | 78 | 285 | 450 | 890 | 1132 |

| 140 | 60 | 140 | 300 | 190 | 230 | 200 | 500 | 380 | 400 | 120 | 110 | 285 | 500 | 930 | 1182 |

| lwo pressure system | |||||

| pump type | output L/min | pressure MPa | motor | ||

|

type |

power kW | velocity rpm | |||

| LBZ-25 | 25 | 0.4 | Y90S-4,V1 | 1.1 | 1400 |

| high pressure system | |||||

| pump type | output L/min | pressure MPa | motor | ||

|

type |

power kW | velocity rpm | |||

| 2.5MCY14-1B | 2.5 | 31.5 | Y112M-6,B35 | 2.2 | 940 |

|

filling temperature ℃ |

cooling system |

tanker vjolume m3 |

filter area m2 |

filter percision mm |

power of heater kW |

|||

|

cooling area m2 |

water temperature ℃ |

pressure MPa |

water consume m3/h |

|||||

| 40±3 | 3 | ≤30 |

0.2≤0.4 |

1.5 | 0.8 | 0.19 | 0.05 | 3*4 |

1.pressure controller(2 each of high , low)

2.pressure gage(1 each of high , low)

3.pressure gage switch

4.pressure interface of pump

5.pressure interface of filling

6.differential pressure interface of filter

7.duplex pressure gage

8.electric contact pressure thermometer

9.pressure interface of high pressure

| lwo pressure system | ||||

| output L/min | pressure MPa | motor | ||

|

type |

power kW | velocity rpm | ||

| 63 | 0.4 | Y132S-4,V1 | 5.5 | 1400 |

| high pressure system | ||||

| output L/min | pressure MPa | motor | ||

|

type |

power kW | velocity rpm | ||

| 2.5 | 31.5 | Y112M-6,B35 | 2.2 | 940 |

|

filling temperature℃ |

cooling system |

tanker vjolume m3 |

filter area m2 |

filter percision mm |

power of heater kW |

|||

|

cooling area m2 |

water temperature ℃ |

pressure MPa |

water consume m3/h |

|||||

| 40±3 | 3 | ≤30 |

0.2≤0.4 |

1.5 | 0.8 | 0.19 | 0.05 | 3*4 |